Generation

The actual capacity of CEM’s generation consists of two power stations located on the Coloane Island namely Coloane Power Station A (CCA) and Coloane Power Station B (CCB), which are with 271.4 MW and 136.4 MW of installed capacity respectively.

The type of generation technology deployed are the low speed diesel generator (CCA) and the combined cycle gas turbine (CCB). These two types of generating units make up of 66.6% and 33.4% of total capacity installed and accounted 13.0% and 87.0% of total electricity generation in 2021 respectively.

In 2021, the gross energy demand was 5,648.8 GWh, of which 286.9 GWh was produced by CEM and 5,361.9 GWh has acquired from external suppliers. The energy breakdowns between CEM generation and energy acquisition were 5% and 95% respectively. The annual growth rate is 5%. The peak demand was 1,037.4 MW.

Coloane Power Station A

Generator Type | Commercial Operation | Installed Capacity | ||

|

| MW | MVA | |

Steam Turbine | G01 | 1978 | 20.0 | 25.0 |

| G02 | 1978 | 20.0 | 25.0 |

Diesel Fuel-oil | G03 | 1987 | 24.0 | 30.0 |

| G04 | 1988 | 24.0 | 30.0 |

| G05 | 1991 | 38.6 | 48.3 |

| G06 | 1992 | 38.6 | 48.3 |

| G07 | 1995 | 53.1 | 66.4 |

| G08 | 1996 | 53.1 | 66.4 |

| Total | 271.4 | 339.3 | ||

Coloane Power Station B

Generator Type | Commercial Operation | Installed Capacity | ||

MW | MVA | |||

Cycle Combined | GT1 | 2002 | 45.1 | 56.4 |

| GT2 | 2003 | 45.1 | 56.4 |

| ST1 | 2003 | 46.2 | 57.7 |

| Total | 136.4 | 170.5 | ||

New Combined Cycle Gas Turbine Generator

Lower Emissions

| Generator Type | NOx | SOx | CO | CO2 |

| Macau Power Station (CMC) | 13.32 | 5.10 | 0.79 | 809.15 |

| Coloane Power Station Units G03 / G08 | 2.33 | 1.29 | 0.42 | 319.36 |

| New Combined Cycle Gas Turbine (CCGT) | 0.29 | 0.01 | 0.00 | 42.54 |

| Reduction* | -97.8% | -99.8% | -100% | -94.7% |

Unit: g/kWh

*New CCGT vs former Macau Power Station

System Dispatch Center

The System Dispatch Center is located at Porto Exterior Substation, which is responsible for real-time monitoring of the entire power system. Through coordinating the network operations in generation, transmission and distribution by the System Dispatch Center, the optimal performance of the power system is achieved and ensure delivering the safe and reliable electricity supply to customers.

CEM installed the Remote Terminal Units (RTUs) and power communication network in all HV primary substations and MV customer substations. Large amount of real-time data including operational status, alarm and measurement from substations are transmitted to the centralized SCADA/EMS/DA system through the communication network. It is realized for the dispatchers to closely monitor and control the entire power system. When power outage occurs, the dispatchers can identify the fault situation based on the real-time alarms and issue the remote control to restore the power in fast response via the Supervisory Control and Data Acquisition (SCADA) system, thus it minimizes customers’ outage time. The Energy Management System (EMS) can provide the in-depth analysis of state-estimation, contingency analysis, power flow, etc., to assist System Dispatch Center on the right decision making of network operation, as well as the optimization of daily operation in the power system.

In order to continuously improve the stability and reliability of the MV distribution network, besides of the traditional Open Rings using Power Line Carrier (PLC) technology, CEM implemented the Closed Ring Distribution System in 2008 that can automatically determine and quickly isolate the fault location. Additionally, in order to fully realize the smart grid development, CEM continues to enhance the reliability of MV communication.

Considering the System Dispatch Center has been in operation for around 20 years and its location, office space, auxiliary systems and equipment are no longer adequate to accommodate the current and future needs, CEM is planning to build the New Dispatch Center and the current control center at Porto Exterior Substation will upgrade as the future backup dispatch center. At the same time, SCADA/EMS/ADMS system will be upgraded adopting state of the art technologies to enhance the intelligence of dispatch management.

In order to achieve the corporate vision of “To be a leading energy services provider in Asia”, CEM will continue to strengthen the implementation of smart grid including various advanced technologies like smart metering, EV charging facilities, renewable energy, network automation, cyber security, asset management, smart street lighting, common services tunnel, etc. Also, CEM will proactively accelerate the digital transformation so as to optimize business processes and operational efficiency. It would further improve the reliability of power supply, provide customers with the best solutions and meet the energy demand of the future society.

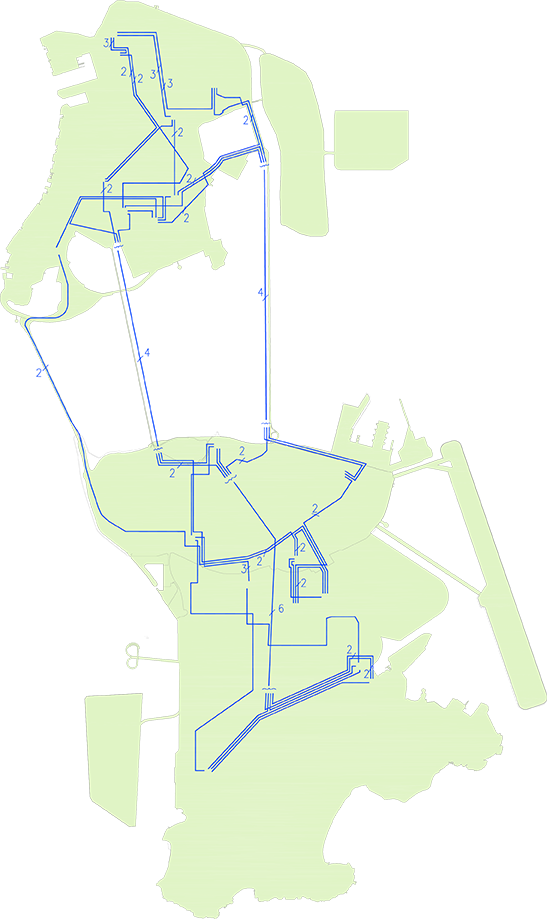

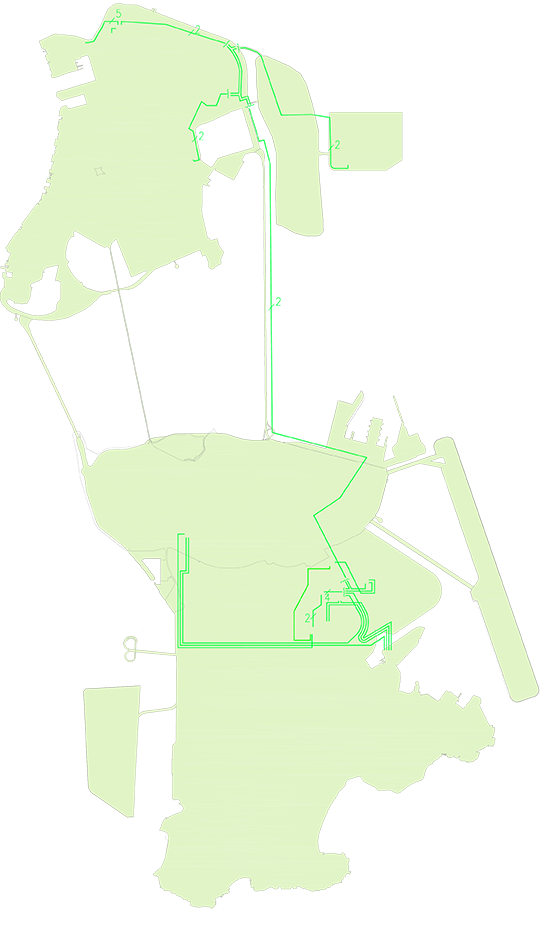

Transmission & Distribution

CEM’s transmission system operates at 220kV, 110kV and 66kV, while distribution is mainly at 11kV and 400/230 volts. The supply is 50 hertz alternating current, at 230 volts single-phase or 400 volts three-phase.

Substations

CEM has now in operation 26 primary substations and 8 customer high-voltage switching stations, and also operates 1,686 customer substations and customer switching stations.

Lines and Cables

Power network is made up of underground cables. The main high voltage network operates at 66kV, although some circuits operate at 110kV and 220kV. For distribution purpose, high voltage is initially converted to medium voltage (11kV), and further reduced to 400/230 volts for customer use.

CEM’s network comprises 1,058 km high-voltage (220, 110 and 66kV), 2,525 km 11kV medium-voltage and 991 km low-voltage cables.

Interconnections with Guangdong Province

The first 220kV interconnection with Guangdong Power Grid (GPG) has been commissioned since June 2008, consisting of 3 circuits connected with the 220/110kV “Canal dos Patos” substation, with total 1,050 MVA importation capacity. With a second 220kV interconnection with GPG completed in June 2012, consisting of 2 circuits connected with the 220/110kV “Lotus” substation, the total importation capacity was increased to 1,750 MVA. The 3rd circuit connected with “Lotus” substation was commissioned in August 2015, the total importation capacity increased to 2,100 MVA.

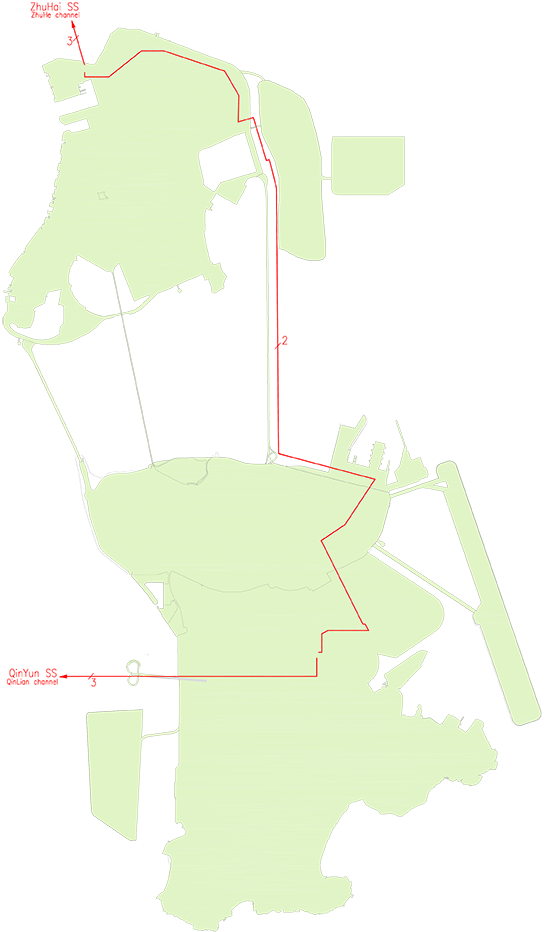

Map of the transmission and interconnection network

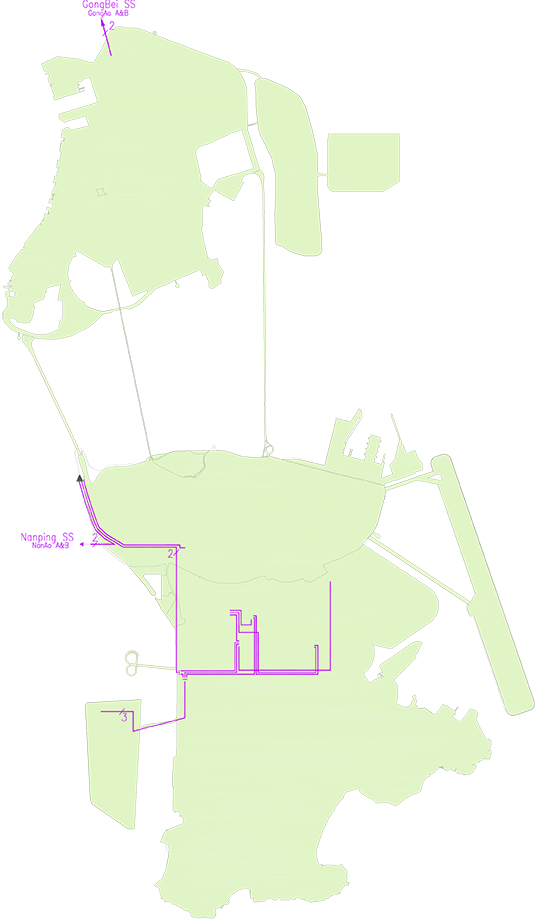

Interconnections with Guangdong Province

The power interconnection between Guangdong and Macau started in 1984 with the transmission of electricity to Macau through 110 kV transmission lines. Since then, the power cooperation between the two places has become increasingly close, and the scale of interconnected electricity has been continuously increasing. The first, second and third interconnections were completed in 2008, 2012 and 2022 respectively, and the Canal dos Patos Substation, Lotus Substation and Pac On Substation were put into operation one after another. Currently, the Guangdong-Macau power grid is linked by eight circuits of 220kV main supply lines and four circuits of 110kV backup lines, forming a transmission network with three 220kV interconnections, namely the ‘North, Central and South’, with a transmission capacity of 1,700 MW to Macau.

Login

Login